In today’s fast-paced business world, warehouses play a crucial role in the supply chain. Nonetheless, managing and organizing these facilities can prove challenging. This is where Warehouse Control Systems come into play.

Are you eager to understand the operations of warehouses and distribution centers? Do you ever wonder how they efficiently manage their inventory and fulfill orders?

This blog will take a deep dive into the realm of WCS and investigate its diverse components and functions. So, buckle up as we uncover the world of warehouse control systems.

What is a WCS Warehouse Control System?

A warehouse control system (WCS) is a powerful software tool designed to manage and streamline inventory flow within a warehouse or distribution center.

Its purpose is to coordinate various subsystems, including carousels, sorters, conveyors, and palletizers, to ensure seamless inventory management, from the moment goods are received to their eventual shipment.

What Are the Functions of a WCS?

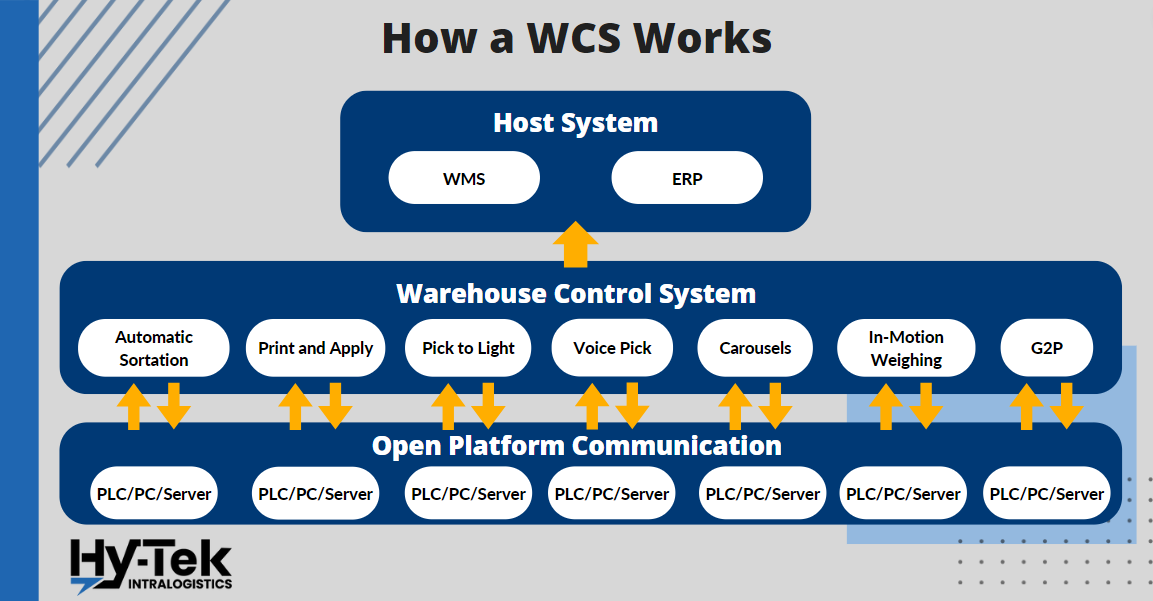

Warehouse Control Systems (WCS) play a crucial role in warehouse management as they serve as the middleware between the Warehouse Management System (WMS) and the floor-level controls of various automation systems. These automation systems, also known as “Islands of Automation,” include:

- Pick/put to light

- Carousels

- Voice pick

- Goods-to-person systems

To ensure that automation completes its designated functions accurately, a WCS typically receives information from the host system, which includes:

- order profile information

- lane assignment

- labeling data

- weight targets

What are the Advantages of WCS?

Warehouse Control Systems (WCS) have become an integral part of modern warehouse management, offering several advantages to businesses that rely on them. Here are some benefits of using a WCS:

Increases Productivity and Efficiency

It ensures that all workflows and functions run smoothly, allowing for increased productivity and efficiency.

Improves Accuracy

A WCS helps minimize errors in picking and loading orders while allowing your employees to make informed decisions.

Saves Time and Costs

By optimizing routes and assigning tasks to available resources, a WCS saves time and reduces labor costs.

Provides Real-time Visibility

Utilizing a Warehouse Control System (WCS), managers gain instantaneous visibility into the daily activities of warehouse personnel, permitting them to closely follow and observe their operations at any time.

For those seeking to enhance their efficiency and simplify their operations, investing in WCS could be a valuable choice as it can assist e-commerce businesses with intricate warehousing requirements.

How Does a WCS Differ from other systems used in a Warehouse?

A Warehouse Control System (WCS) differs from other systems used in a warehouse, such as Warehouse Management Systems (WMS) and Warehouse Execution Systems (WES), in terms of its primary responsibility.

While a WMS is primarily responsible for managing overall warehouse operations and tracking orders from the moment they are received until they are shipped out, a WCS is specifically accountable for controlling the physical flow of inventory using material handling equipment and systems.

Warehouse Management System (WMS)

A Warehouse Management System (WMS) is software used in various industries, such as manufacturing and retail, to track the movement of goods and materials in and out of the warehouse.

The system optimizes warehouse processes by streamlining how workers pick products and pack orders and provides real-time inventory tracking for efficient order fulfillment.

Warehouse Execution System (WES)

A Warehouse Execution System (WES) is software that optimizes and manages the physical processes in a warehouse or distribution center, such as picking, receiving, and replenishment.

It typically integrates with other inventory management software like a warehouse management system (WMS) or enterprise resource planning system (ERP).

WES systems provide flexible and efficient material handling processes, both automated and manual, and offer sophisticated process optimization capabilities that greatly enhance productivity, efficiency, and throughput of core DC activities.

How to Choose the Right WCS for Your Business?

Selecting the right WCS Warehouse Control System is critical to the success of your business. Various choices in the market can make it challenging to determine which option is most suitable for your business requirements. To help you in choosing the appropriate WCS for your organization, consider the following tips:

Consider the types of products you store and ship.

If your business deals with perishable items, you may need a WCS with temperature control capabilities.

Assess the size and layout of your facility.

The size and layout of your facility will determine the kind of WCS you need. If you have a large warehouse, you may require a WCS to manage multiple zones or different buildings.

Evaluate the number of SKUs you handle.

A WCS with advanced inventory management features will be suitable for businesses that handle many SKUs.

Analyze your order volume.

Your order volume will determine the level of automation required in your warehouse. If your business deals with a high order volume, you may need a WCS with advanced picking and sorting capabilities.

Consider your labor force.

The WCS you choose should be easy to use and require minimal employee training. A user-friendly WCS will save you time and money on training.

Evaluate your budget.

Your budget will also play a significant role in selecting your WCS. Make sure you choose a WCS that offers the features you need at a reasonable cost.

Ensure the WCS is scalable.

It’s essential to choose a WCS that can grow with your business. A scalable WCS will allow you to add new features and functionalities as your business expands.

Consider these factors so you can choose the right WCS for your business, which can increase efficiency and productivity in your warehouse.

How Can Hopewell Logistics Help Improve Your Warehouse Management?

Hopewell Logistics offers warehouse solutions to businesses of all sizes. We specialize in providing customized solutions for warehousing needs. Our expertise lies in integrating technology and optimizing warehouse operations to maximize productivity and efficiency.

We can help improve warehouse management through a Warehouse Control System (WCS). This system can automate and optimize warehouse processes, such as:

- Inventory management

- Order picking

- Shipping

This resulted in reduced labor costs, improved accuracy, and increased throughput. With WCS, businesses can also gain real-time visibility into their warehouse operations, enabling them to make data-driven decisions and respond quickly to changing market demands.

By partnering with Hopewell Logistics, businesses can streamline their warehouse operations and achieve greater operational efficiency.

Unleash the Full Potential of Your Warehouse with WCS—Contact Hopewell Logistics Today!

Warehouse Control Systems (WCS) are irrefutably essential in optimizing warehouse operations and improving decision-making. They offer crucial insights, enabling businesses to remain competitive in a fast-paced market.

To select the most ideal WCS, businesses must evaluate their needs and choose a scalable system with the necessary features at a reasonable cost.

At Hopewell Logistics, we offer expert assistance in finding the right WCS for your business, unleashing its full potential. Take advantage of the efficiency offered by WCS and optimize your warehouse operations today! Contact us and experience the difference.